All pictures related to our company and products on the website are real pictures taken on the company. We have the right to publish, authorship, modify, protect the integrity of the pictures , copy, publish, exhibition, disseminate on the Internet and other rights. Without the permission of tour company, unable to sign, copy and disseminate on the Internet for commercial purposes. Unauthorized commercial use, will retain the right to pursue legal liability.

To our customers:

As a global leading brand of MoSi2 series products, YTTORCH brand has always been foucs on producing high-quality MoSi2 series products, which arefavored and trusted by customers.

In recent years, there are Low quality MoSi2 heating elements faked our brand and sold in the market, which has cause an adverse effect on our reputation, and seriously damaged the interests of the customers. In order to strengthen YTTORCH brand management and prevent customers from being deceived and causing unnecessary losses , We call on relevan customers to purchase through regular ways and hereby make the following statements:

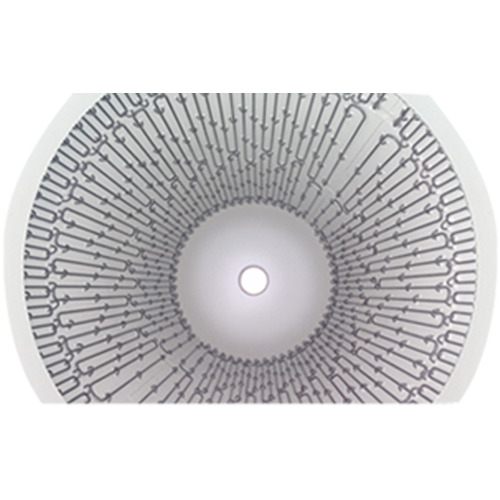

“YTTORCH” brand MoSi2 heating elements has the following characteristics of anti-counterfeiting marks:

The logo applied to the details of the product and packaging , mainly includes: torch shape image logo and “YTTORCH” word mark .They will be marked in the form of individual or combination on the details of the product and packaging.

we will strictly deal with the counterfeit "YTTORCH" brand behavior to ensure interests of the consumers. our company reserves the right to pursue legal responsibility for fake behavior

Disclaimer: The market is risky, choose carefully! This article is for reference only, not for sale basis.

MoSi2 was discovered in 1906, silicon and molybdenum under different conditions, can form MoSi3, Mo5Si3 and MoSi2. MoSi2 can form SiO2 protective layer on the surface at high temperature to prevent further oxidation, whice has good high temperature oxidation resistance and excellent electrical conductivity. MoSi2 melting point is 2030℃, which is a kind of ultra-high temperature structural material.

MoSi2 heating elements is a kind of electric heating element based on the molybdenum disilicide material , also named "MoSi2 heating rods ", "MoSi2 heater ", "MoSi2 resistance " "二矽化钼加热元件 ", etc., Its high temperature performance is excellent; It has similar properties to metals and ceramics. when it wok in the low temperature , the MoSi2 material strength is higher, greater crisp characte (similar to ceramics). hen it wok in the low temperature above 1000℃ ,the MoSi2 has metal-like soft plasticity. In addition to ordinary U shape, L shape and W shape, it can also be processed into spiral shape and other special shapes.

Silicon is a chemical element, its chemical symbol is Si, formerly known as 矽 (Taiwan China uses the word "矽" so far), silicon is also a very common element, but it rarely appears in nature in the form of a single substance, but in the form of complex silicate orSiO2, widely present in rocks, gravel, dust. Molybdenum is a refractory rare metal, its chemical symbol is Mo, molybdenum melting point is 2620℃, due to the strong interatomic bonding force, so the strength is very high at atmospheric temperature and high temperature. It has small expansion coefficient, high conductivity and good heat-conducting property.

The early application of MoSi2 heating elements is mainly as a high temperature and corrosion resistant coating protection material on the surface of metal matrix, and it is first applied to the coating of gas turbine components, jet engine combustion chambers and missile combustion chambers. With the continuous development and innovation of technology, the application field has also been expanded to update, and is now widely used in metallurgy, steelmaking, glass, ceramics, refractory materials, crystals, electronic components, semiconductor materials research, manufacturing and other fields. Especially for the production of High Performance and high- precision ceramics, high-grade intraocular lens, high- precision structural ceramics , glass fiber, optical fiber and high-grade alloy steel. (Such as: Muffle furnace, dental furnace, tunnel kiln, roller kiln, glass kiln, smelting furnace, diffusion furnace, etc.)

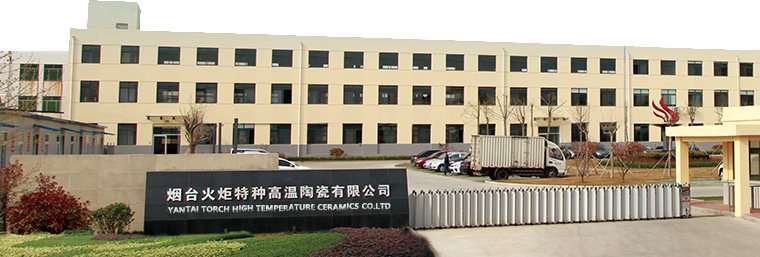

Yantai Torch Special High Temperature Ceramics Co.,

Ltd

Yantai Torch Special High Temperature Ceramics Co.,

Ltd 0535-6891306

0535-6891306  0535-6891305

0535-6891305  0535-6891307

0535-6891307 yttorch@torch-mosi.com

yttorch@torch-mosi.com www.torch-mosi.com

www.torch-mosi.com No. 9 Xiulin Road, Laishan District, Yantai

City

No. 9 Xiulin Road, Laishan District, Yantai

City