Product Information

| Product Name | Dedicated type MoSi2 heating elements |

| Brand | YTTORCH |

| Place Of Origin | CHINA |

| Model No | VOS-56-002 for diffusion furnace |

| Recommended Temperature Grade Type | MR1800type TC1800 type TC1700type |

| Shape | Customizable |

| Size | Customizable |

| Heating Element Temperature (Air Environment) | 1700℃ |

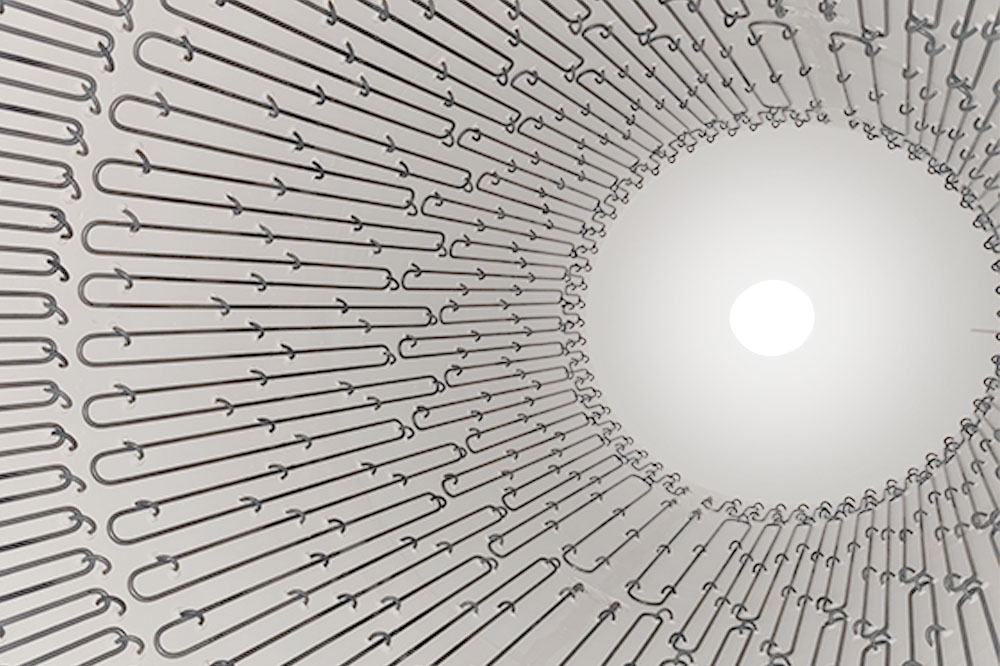

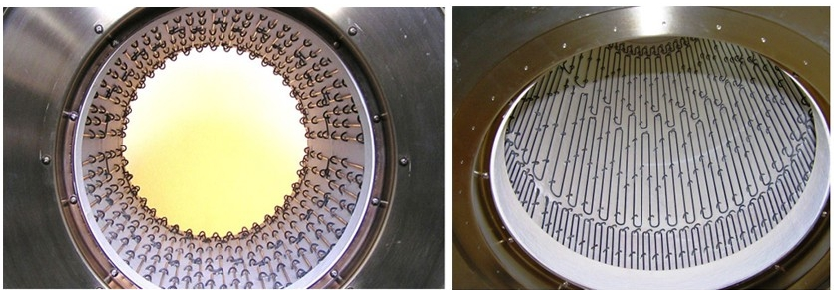

| Features | 1.This product is precision machiningwithhigherheatingpower and itcanprovide uniform thermal field forelectric furnaces; 2.Corresponding shapes can be manufactured basedonoperating requirement of customers.Thisproduct can maintain a certain performance in use with long service life; 3.Comparing with the metal wire,it can bear greater surface load and rapid temperature increasing system(fast coolingand temperature increasing); 4.It can matchwithvarious dimensionsof wafers from small size to large size,namely multi-application 5.It can ensurethecleannessofrelevant equipment if being used underhigh temperature. |

| Application Range | Electric furnaces for semiconductor wafers; Cylinder-shaped electric furnaces |

Product Advantage

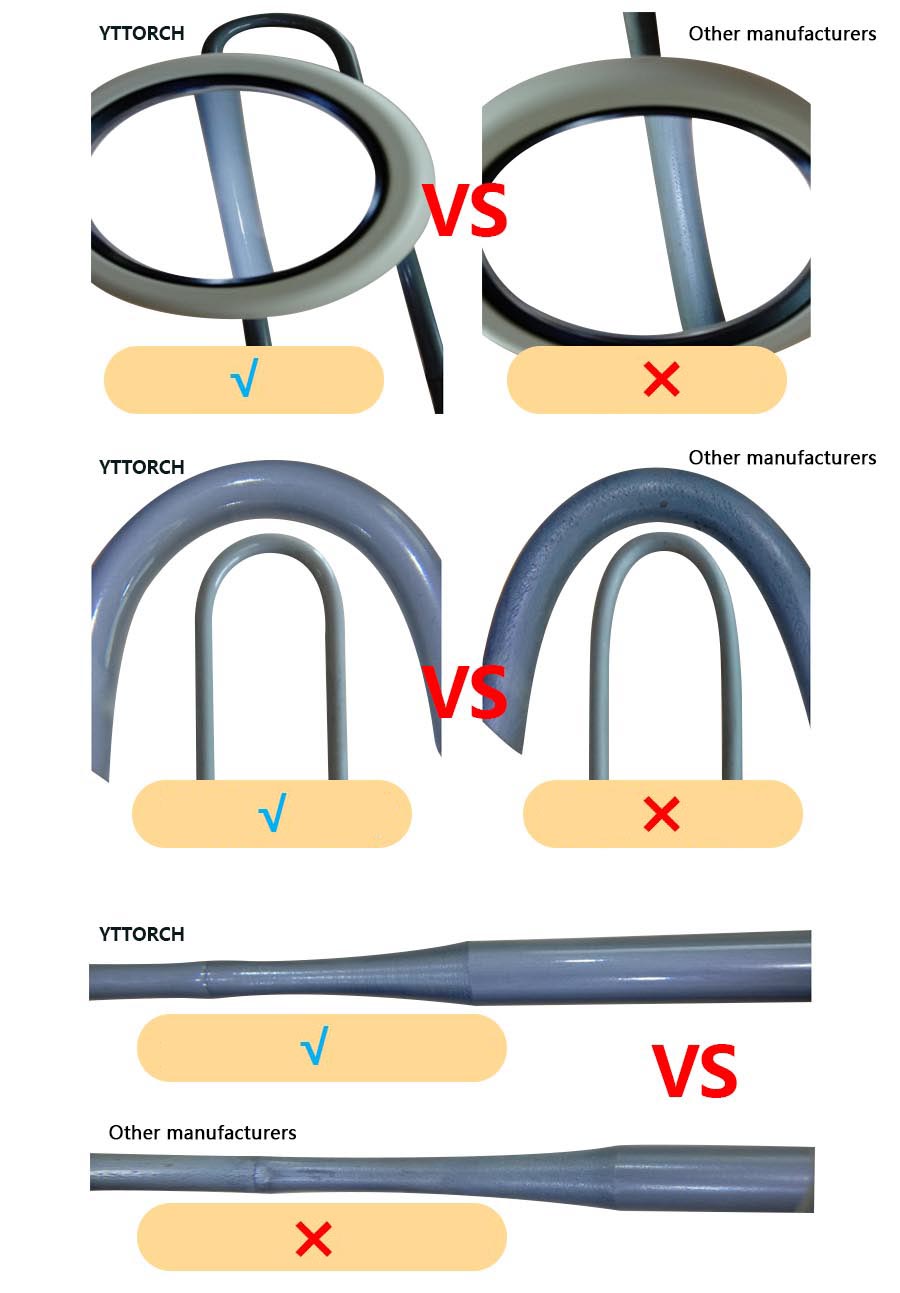

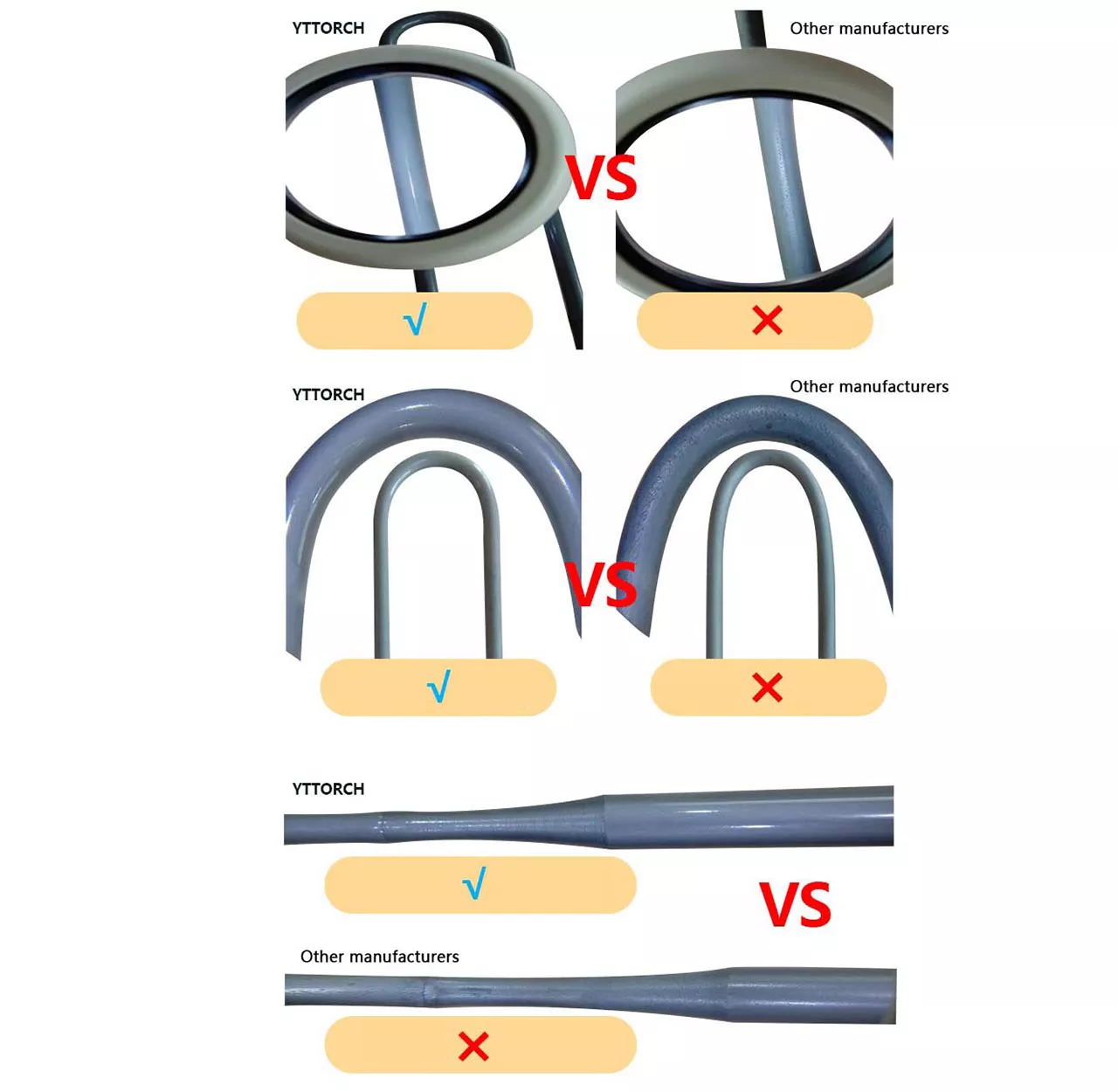

1.Appearance:Good appearance without cracks and obvious scratches

2.Diameter:The uniform diameter is favorable for providing uniformheating fiel

3.Protective Layer:Protective Layer is compact and good,not easay to fall off

4.Welding Spot:Welding Spot is firm which has strong impact resistance and is not easy to break

5.Bending:The geometry of the bending part is accurate

6.Density:High density, higher conductivity, faster heating, lower power consumption, help save production cost

7.High tenacity :The product is shaped in hot-working process, better tenacity , can meet more customized needs

8.High Temperature Strength:Good high temperature strength, can bear higher surface load in high temperature environment, not easy to get out of shape

9.Purity:High purity. TC1900, TC1850 type is especially suitable for high-end dental furnaces and lab electric furnaces

10.Temperature Resistance:High temperature resistance, not easy to overheat damage

11.ISO9001 quality control system and professional technical team to ensure stable quality

Technical data

Physical Properties :

| Type | Density-glcm³ | Bending Strength under Room Tem-perature-MPa | Hardness-GPa | Compression Strength-MPa | Water Absorption-% | Thermal Elongation-% |

| TC1700 | 5.8±0.1 | 450 | 11 | >1500 | ≤0.2% | 4 |

| TC1800 | 6.0±0.1 | 500 | 12 | >1500 | ≤0.2% | 4 |

| MR1800 | 5.9±0.1 | 430 | 11.5 | >1500 | ≤0.2% | 4 |

Chemical Properties

MoSi2 Heating Element has the ability to withstand oxidation at high temperatures. This is due to the formation of a thin and adhesive protective layer of quartz glass (SiO2) on the surface. When the element temperature over 1700℃, SiO2 protective layer which melting point is 1710℃ was fused, and because of the surface tension, it fused into drops, which is useless. However, when element continue working in oxidizing atmospheres, the SiO2 protective layer is spontaneously rebuilt.

Notice: It is no good to use Molybdenum Disilicide Heating Element for Long-term within a range of 400-700℃, otherwise the element will be powdered by the strong low temperature oxidation.

Indicators in Different Atmospheres

| Atmosphere | Type 1700 | Type1800 |

| Air | 1700 | 1800 |

| Nitrogen | 1600 | 1700 |

| Argon,Helium | 1600 | 1700 |

| Dry hydrogen dewpoint -80℃ | 1150 | 1150 |

| Moist hydrogen dewpoint 20℃ | 1450 | 1450 |

| Exogas(Ex.10%CO₂,5%CO and 15%H₂) | 1600 | 1700 |

| Endogas(Ex.40%H2 and 20%CO) | 1400 | 1450 |

| Cracked and partially burnt ammonia (8%H₂) | 1400 | 1450 |

PACKING & DELIVERY

Delivery

For small orders,the delivery time is1~3working days or 7 working days;For large orders or urgent orders,the delivery time can be negotiated.

The product may be transported by by air, boat, railway, Express etc.

A/S

Within 7 days after receiving the product, Please confirm whether there is any damage on the outer packing and product .

If If the product is damaged, send the photos or video about the damaged product and outer packing to us , We will provide

you with the after-sales service.

ABOUT US

Dedicated and professional:Since 1998 ,Focus on the production of Mosi2 series products

Source factory:>13000㎡

Number of employees:>100

Annual production:>60T

Patented technology & ISO9001Certification(patent type: invention patent certificate,Patent number:ZL 99 1 12205.4 International Patent Main classification number: C01B 33/06 Independent patented technology

Technical support:Customizable

Customer service:Professional & effective

MOQ 1PCS:Treat every customer as a VIP guest

Fast Deliver: Timely delivery rate 100%

Worry-free After-sales:Excellent after-sales team

Export country: The United States,Europe,Japan, Korea, Southeast Asia etc.

| Product Standard specifications | |||||||||

| Diameter(mm) φd(hot zone)/ φC(cold zone) |

shape |

length(mm) Le(hotzone)/ Lu(cold zone) | a(mm) | g(mm) | f(mm) | h(mm) | n(mm) | ||

|

Standard |

Minimum |

Standard |

Minimum | ||||||

| 3/6 |

U,L ,W or customized |

customized | 25 | 12 | 15 | 30 | 10 | 40 | 35 |

| 4/9 |

U,L ,W or customized |

customized | 25 | 15 | 20 | 30 | 10 | 50 | 45 |

| 6/12 |

U,L ,W or customized |

customized | 50 | 25 | 25 | 45 | 15 | 90 | 70 |

| 9/18 |

U,L ,W or customized |

customized |

60 | 35 | 32 | 75 | 20 | 135 | 110 |

| 12/24 |

U,L ,W or customized |

customized |

80 | 50 | 40 | 100 | 35 | / | / |

Yantai Torch Special High Temperature Ceramics Co.,

Ltd

Yantai Torch Special High Temperature Ceramics Co.,

Ltd 0535-6891306

0535-6891306  0535-6891305

0535-6891305  0535-6891307

0535-6891307 yttorch@torch-mosi.com

yttorch@torch-mosi.com www.torch-mosi.com

www.torch-mosi.com No. 9 Xiulin Road, Laishan District, Yantai

City

No. 9 Xiulin Road, Laishan District, Yantai

City