Product Information

| Product Name | Dedicated type MoSi2 heating elements |

| Brand | YTTORCH |

| Place Of Origin | CHINA |

| Model No | Dedicated type for dental furnace |

| Recommended Temperature Grade Type | TC1900 type |

| Shape | Customizable |

| Size | Customizable |

| Heating Element Temperature (Air Environment) | 1850℃ |

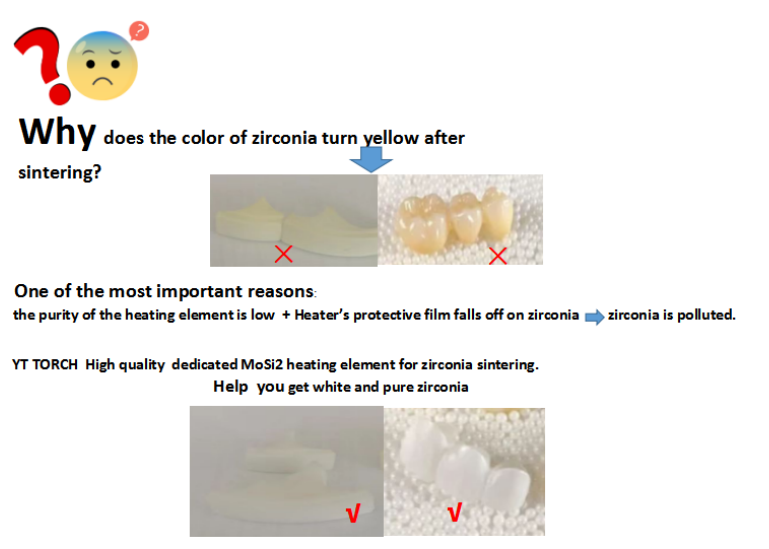

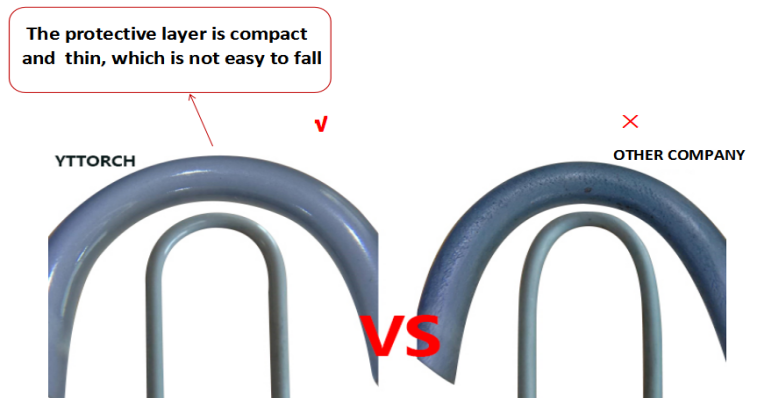

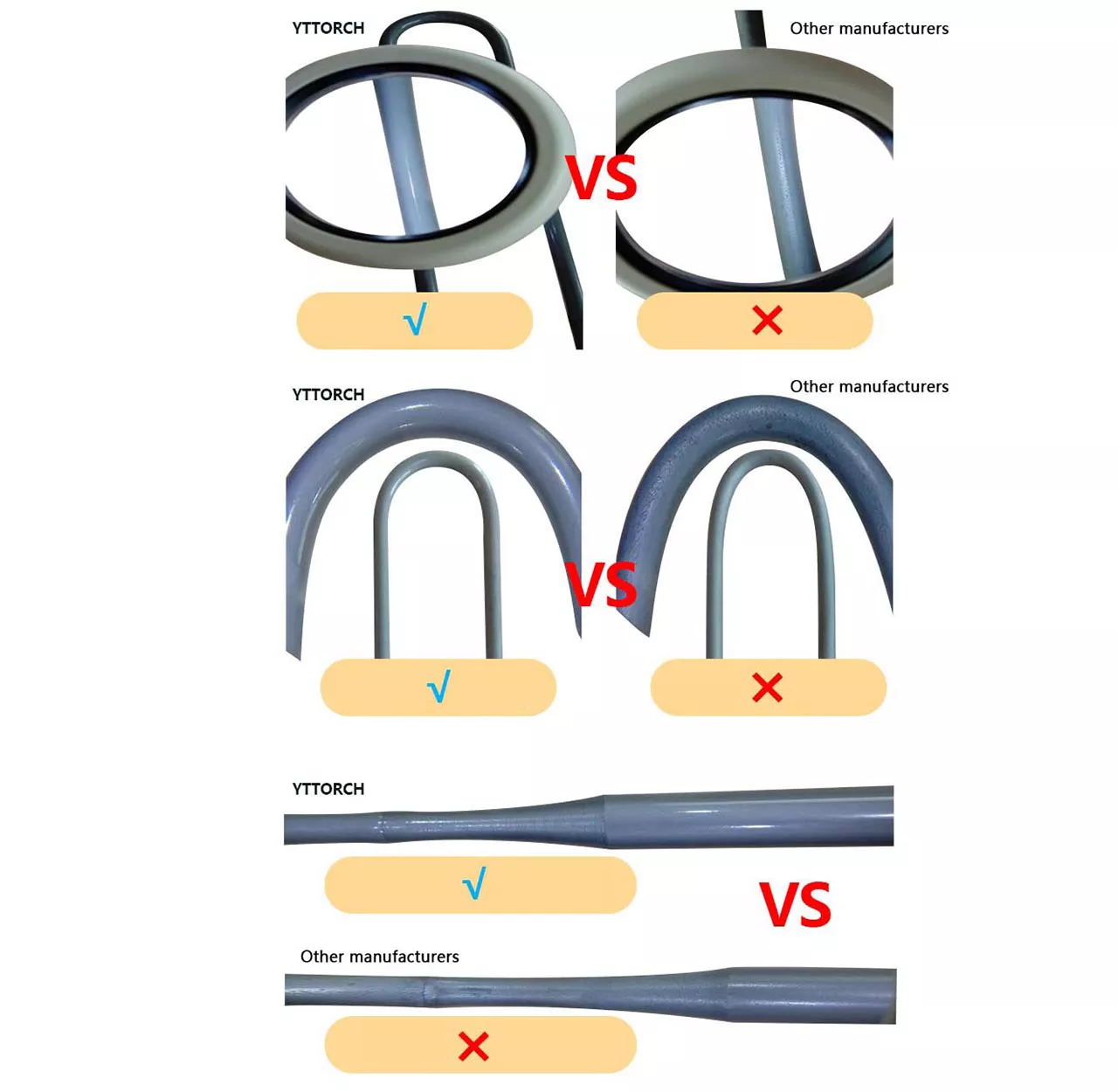

| Features | 1.The heating elementhas highpurity,which can reduce the impurity contenttothe utmostextent |

| Application Range | Precise electric furmaces having higher requiremen on heating elements such as electric furnacesfor dentistry Electric furnaces with fast temperature increasing and decreasing, frequent use and short sintering period |

* TC1900 Type has high purity, which can reduce the impurity content to the utmost extent. It is especially suitable for a dental furnace for sintering zirconia

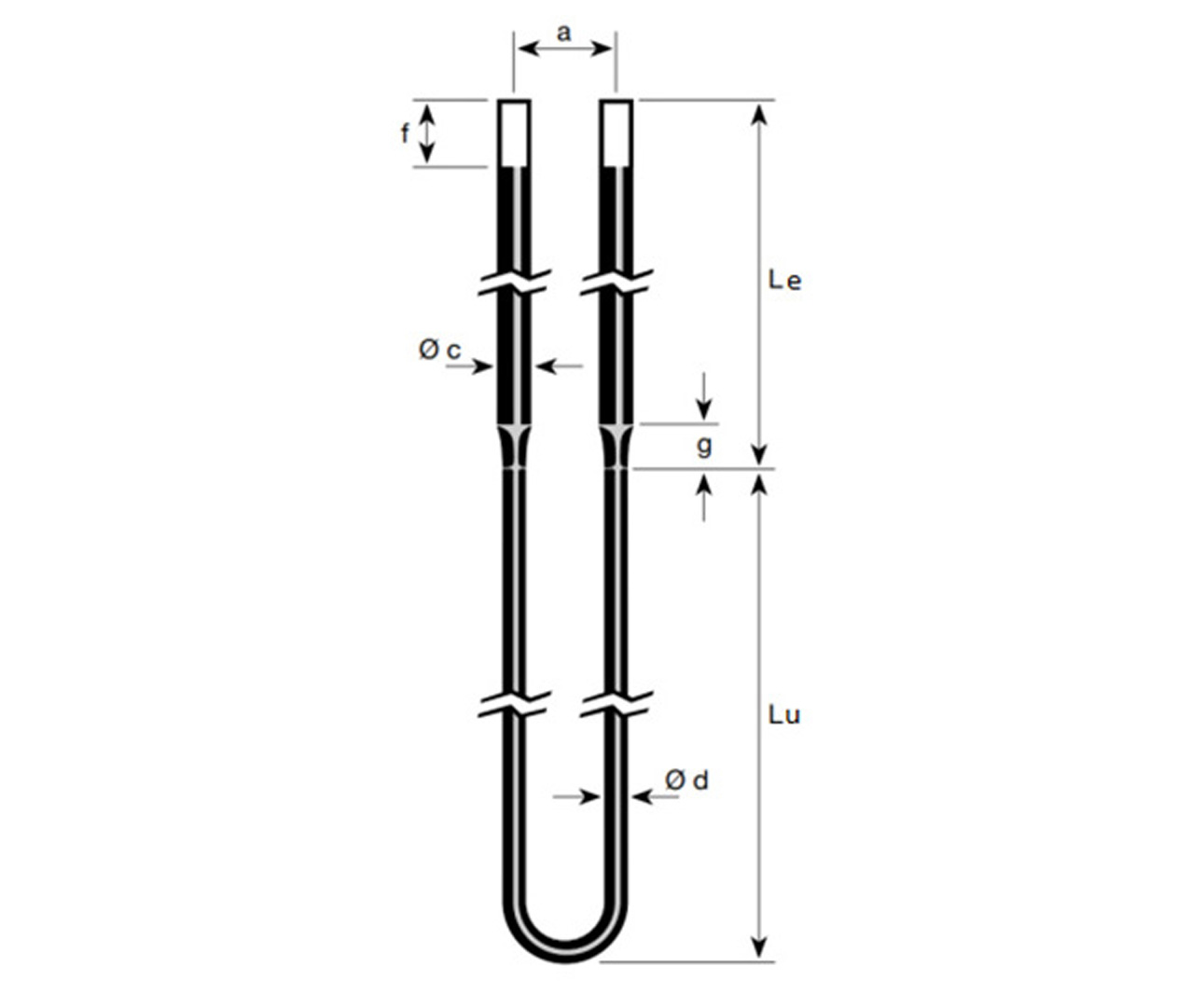

| Product Standard specifications | |||||||||

| Diameter(mm) φd(hot zone)/ φC(cold zone) |

shape |

length(mm) Le(hotzone)/ Lu(cold zone) | a(mm) | g(mm) | f(mm) | h(mm) | n(mm) | ||

|

Standard |

Minimum |

Standard |

Minimum | ||||||

| 3/6 |

U,L ,W or customized |

customized | 25 | 12 | 15 | 30 | 10 | 40 | 35 |

| 4/9 |

U,L ,W or customized |

customized | 25 | 15 | 20 | 30 | 10 | 50 | 45 |

| 6/12 |

U,L ,W or customized |

customized | 50 | 25 | 25 | 45 | 15 | 90 | 70 |

| 9/18 |

U,L ,W or customized |

customized |

60 | 35 | 32 | 75 | 20 | 135 | 110 |

| 12/24 |

U,L ,W or customized |

customized |

80 | 50 | 40 | 100 | 35 | / | / |

Technical data

Physical Properties:

Type | Bulk Density-g/cm3 | Bending Strength-MPa | Hardness-GPa | Compression Strength-MPa | Water Absorption-% | Thermal elongation-% |

TC1900 | 7.0±1 | 360 | 10.5 | >1500 | ≤0.2% | 4 |

Chemical Properties

MoSi2 Heating Element has the ability to withstand oxidation at high temperatures. This is due to the formation of a thin and adhesive protective layer of quartz glass (SiO2) on the surface. When the element temperature over 1700℃, SiO2 protective layer which melting point is 1710℃ was fused, and because of the surface tension, it fused into drops, which is useless. However, when element continue working in oxidizing atmospheres, the SiO2 protective layer is spontaneously rebuilt.

Notice: It is no good to use Molybdenum Disilicide Heating Element for Long-term within a range of 400-700℃, otherwise the element will be powdered by the strong low temperature oxidation.

Indicators in Different Atmospheres

| Atmosphere | TC1700 | TC1800 | TC1850 | TC1900 |

| Air | 1700 | 1800 | 1830 | 1850 |

| Nitrogen | 1600 | 1700 | 1700 | 1700 |

| Ar Ne Argon, Helium | 1600 | 1700 | 1700 | 1700 |

| Dry Hydrogen (dew point)-80℃ | 1150 | 1150 | 1150 | 1150 |

| Wet Hydrogen (dew point)-20℃ | 1450 | 1450 | 1450 | 1450 |

| Exogas(e.g. 10% CO2, 50% CO, 15%H2) | 1600 | 1700 | 1700 | 1700 |

| Exogas(e.g. 40% CO2, 20% CO) | 1400 | 1450 | 1450 | 1450 |

| Cracked and partially burnt ammonia(8%H2) | 1400 | 1450 | 1450 | 1450 |

Yantai Torch Special High Temperature Ceramics Co.,

Ltd

Yantai Torch Special High Temperature Ceramics Co.,

Ltd 0535-6891306

0535-6891306  0535-6891305

0535-6891305  0535-6891307

0535-6891307 yttorch@torch-mosi.com

yttorch@torch-mosi.com www.torch-mosi.com

www.torch-mosi.com No. 9 Xiulin Road, Laishan District, Yantai

City

No. 9 Xiulin Road, Laishan District, Yantai

City