Product Information

| Product Name | Dedicated type MoSi2 heating elements |

| Brand | YTTORCH |

| Place Of Origin | CHINA |

| Model No | VOS-56-003 for diffusion furnace |

| Recommended Temperature Grade Type | MR1800type TC1800 type TC1700type |

| Shape | Customizable |

| Size | Customizable |

| Heating Element Temperature (Air Environment) | 1700℃ |

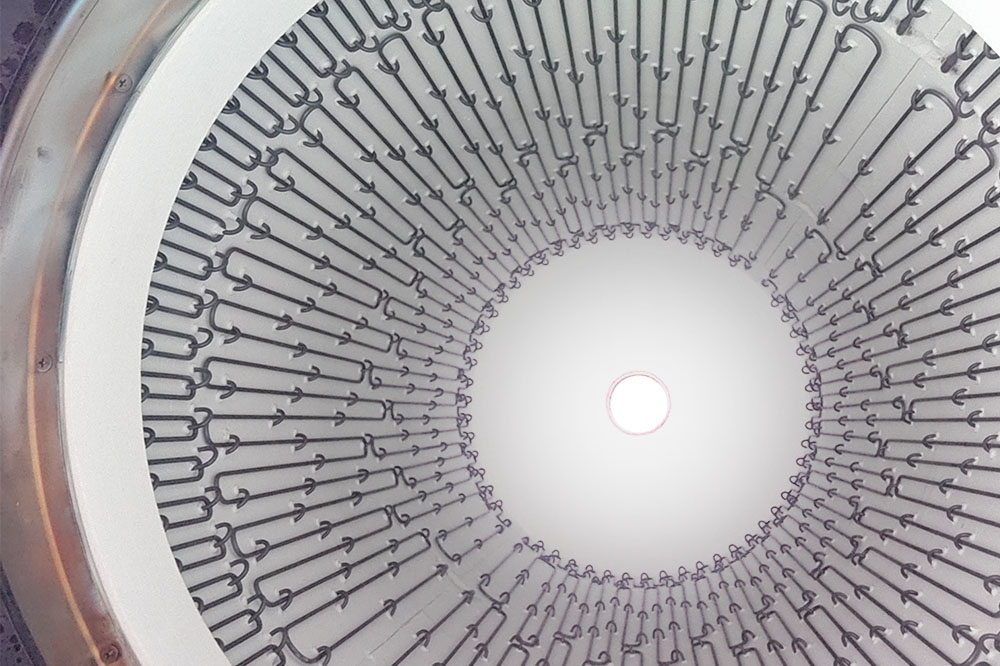

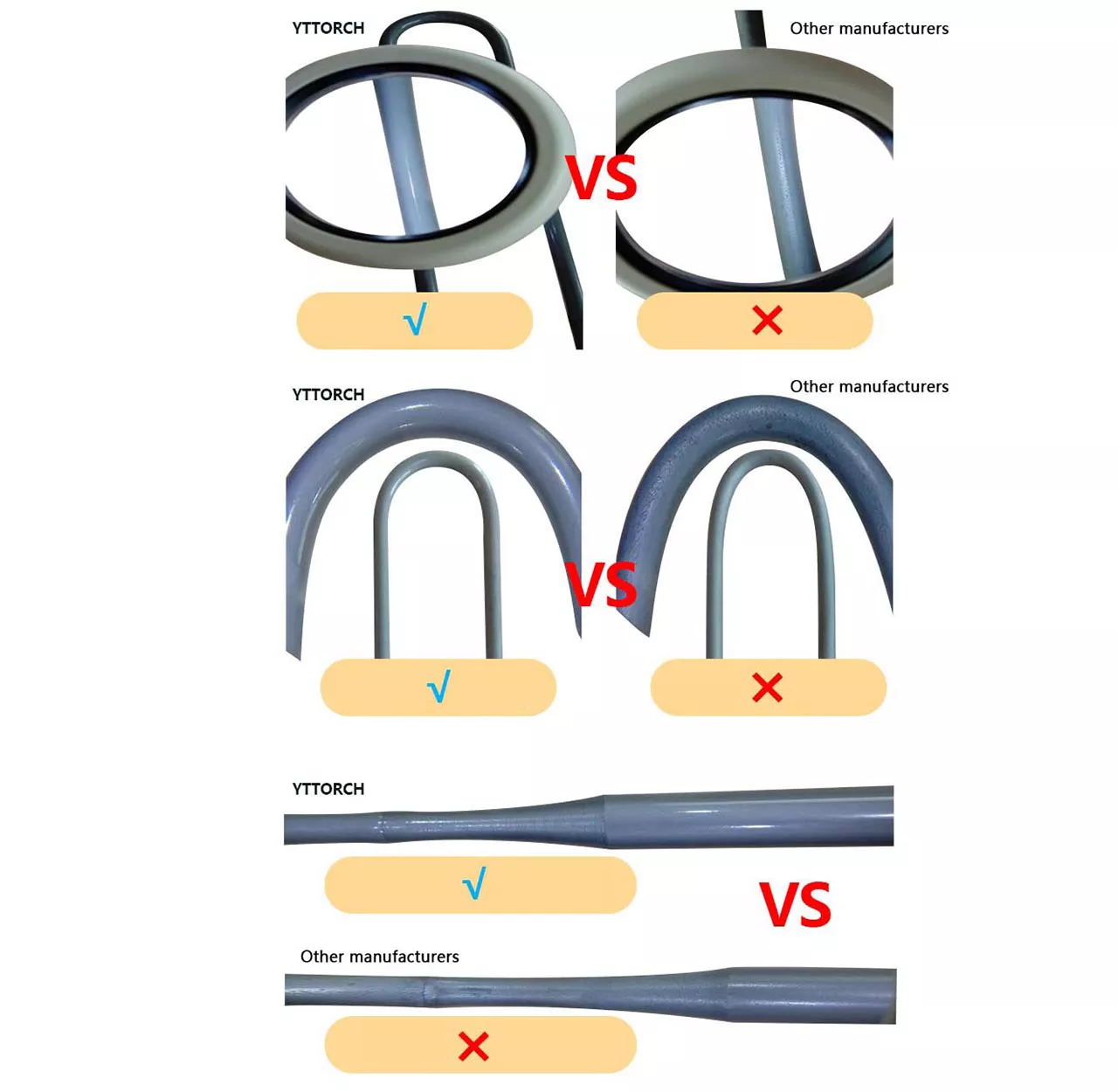

| Features | 1.This product is precision machiningwithhigherheatingpower and itcanprovide uniform thermal field forelectric furnaces; 2.Corresponding shapes can be manufactured basedonoperating requirement of customers.Thisproduct can maintain a certain performance in use with long service life; 3.Comparing with the metal wire,it can bear greater surface load and rapid temperature increasing system(fast coolingand temperature increasing); 4.It can matchwithvarious dimensionsof wafers from small size to large size,namely multi-application 5.It can ensurethecleannessofrelevant equipment if being used underhigh temperature. |

| Application Range | Electric furnaces for semiconductor wafers; Cylinder-shaped electric furnaces |

| Product Type | Density-g/cm3 | Bending strength under room temperature-MPa | Hardness-GPa | Compression Strength-MPa | Water Absorption-% | Thermal elongation-% |

| TC1700 | 5.8±0.1 | 450 | 11 | >1500 | ≤0.2% | 4 |

| TC1800 | 6.0±0.1 | 500 | 12 | >1500 | ≤0.2% | 4 |

| MR1800 | 5.9±0.1 | 430 | 11.5 | >1500 | ≤0.2% | 4 |

| Atmosphere | 1700Type | 1800Type | 1850Type | 1900Type |

| Air | 1700 | 1800 | 1830 | 1850 |

| Nitrogen | 1600 | 1700 | 1700 | 1700 |

| Ar Ne Argon, Helium | 1600 | 1700 | 1700 | 1700 |

| Dry Hydrogen (dew point)-80℃ | 1150 | 1150 | 1150 | 1150 |

| Wet Hydrogen (dew point)-20℃ | 1450 | 1450 | 1450 | 1450 |

| Exogas(e.g. 10% CO2, 50% CO, 15%H2) | 1600 | 1700 | 1700 | 1700 |

| Exogas(e.g. 40% CO2, 20% CO) | 1400 | 1450 | 1450 | 1450 |

| Cracked and partially burnt ammonia(8%H2) | 1400 | 1450 | 1450 | 1450 |

Yantai Torch Special High Temperature Ceramics Co.,

Ltd

Yantai Torch Special High Temperature Ceramics Co.,

Ltd 0535-6891306

0535-6891306  0535-6891305

0535-6891305  0535-6891307

0535-6891307 yttorch@torch-mosi.com

yttorch@torch-mosi.com www.torch-mosi.com

www.torch-mosi.com No. 9 Xiulin Road, Laishan District, Yantai

City

No. 9 Xiulin Road, Laishan District, Yantai

City